Get lots of skiers asking about rebuilding their engines and what to do to make sure the work is correct. Well, if you are buying a used ski, and almost all are used, you should totally disassemble the engine and start fresh on everything. You must realize that buying a used ski for $200 is nice, but if you want to enjoy Jet Skiing, you have to make the ski reliable so that you don’t breakdown and work on your boat every ride.

So disassemble the engine. Clean up all parts. Replace all gaskets and seals. Reassemble the engine up to and including intake and exhaust manifold. Do not install stator or flywheel yet and no real drive coupler. Then do a leakdown test. Most shops will charge about $80+ to do a leakdown test. What is being checked is the ability of the engine to hold pressure. You can easily make your own tester with just a few pieces.

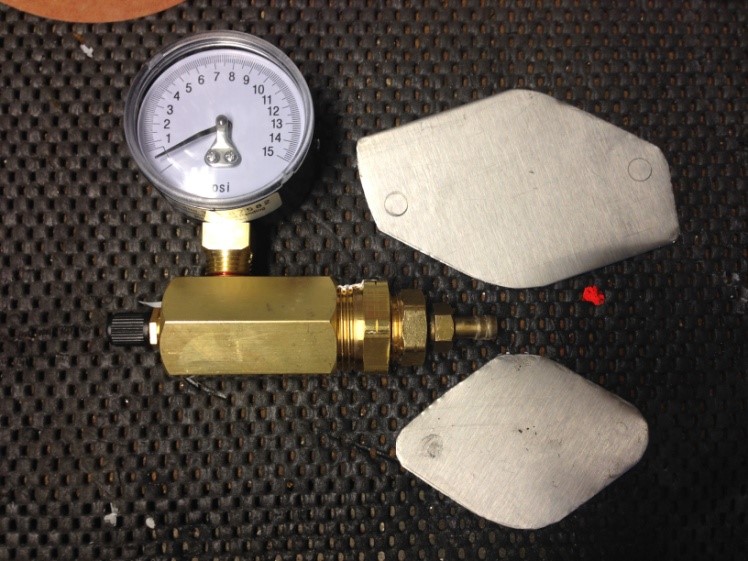

Total investment in tester is $12-$15. If you build block off plates maybe $20.

First you need a gauge that reads to about 15lbs. The smaller total pounds the gauge reads the easier it is to see if you are loosing pressure. A 100 lb. gauge only uses 15% of sweep to measure 15lbs. You are going to pressurize engine 6-10 lbs.

To start I bought a Danco gas pressure gauge at HomeDepot for $9. I also bought a brass reducer and an inlet to fit the log that was on the gauge.

You need a bicycle tire pump.

A Bicycle inner tube

And if you want a sheet of aluminum or stainless steel. I’ll explain later.

Assemble the 3 pieces of the gauge. Cut out inner tube to fit over where carb mounts and where exhaust pipe mounts to exhaust manifold. The rubber covers the hole into manifolds. I made plates to sandwich the rubber pieces mounted at carb and exhaust. If you don’t want to make plates you can mount the carb and the exhaust on over the rubbers that cover the holes.

You also need a long tube (hose) to connect to crankcase pulse fitting. This line normally attaches from case fitting to pump section on Carb.

You need a spray bottle of water and a small amount of soap.

Attach pressure gauge manifold to pulse fitting and attach bicycle pump to schrader valve .

DO NOT USE A COMPRESSOR!!

Pump gauge up to 6-9 psi.

Watch gauge to see if pressure holds steady. It should not loose pressure quickly and a perfect engine will loose no pressure for about 3 minutes. If the gauge shows loss of pressure, spray gasket areas with the soapy water and look for bubbles. You can also use WD40 instead of soapy water. Also test seals. New seals will not normally leak. I find many intake gasket leaks. Spray head gasket areas and base gasket areas.

Once your gauge shows you pass the test, remove the rubber gaskets and pieces holding them in place. Install stator plate, flywheel and flywheel cover. Reinstall your engine knowing that you can use it with confidence.