So after seeing the old school models of the 550 I wanted my own model, but could not come to pay the price I have seen them on eBay. I came across a model made by

zxcvbn on Thingiverse (

https://www.thingiverse.com/thing:3186949) whilst not exactly a 550 came close to what I was looking for.

Just like the original, this project will not only include the model, but further expand (in future issues) into a fully working Radio Controlled version with decals. I didn’t want to simply print a block of a ski, but something that works.

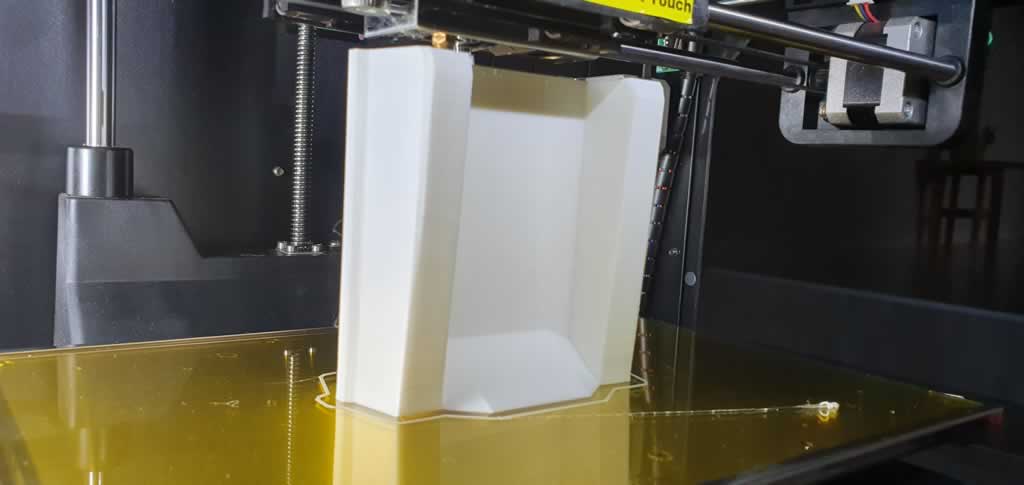

Printing it took 1-2 days. I used PLA on a Maylan M180 printer and Simplyfy3D software on Linux. The STL files from Thingiverse are great quality and built with great precision. Some parts required breaking apart to fit on my sized bed and other parts required supports, but overall, most parts simply printed.

I always ensured that pieces that were designed to either join with epoxy or were designed to sit flush like the hood and hull be placed down on the print bed. This gave an exceptional smoothness as I choose to use Kapton tape.

After printing all the parts, you will end up with a collection of hull parts, hood, pole pieces, servo mounts (for the Radio-Controlled part in the future) and propellers of multiple sizes for trial and error tuning. For those of you familiar with 3D printing models are not smooth like glass but have printer extrusion marks. These marks can be removed with acetone fume baths that melt and smooth but possibly weaken the model or you may find epoxy type baths that smooth imperfections. There is the old school way of sanding and spray painting. That will be the approach in this article.

Once you have cleaned up your parts with a hobby blade, remove any obvious imperfections. Your first job is to glue the 3 pieces of the hull together, along with the 2 parts to the handle pole. You can use superglue; however, I recommend 5-minute araldite epoxy adhesive. When using this stuff, it doesn’t set immediately so you have enough time to align all the parts. The better you get the alignment right the less filling and sanding you will need to do in later steps. Use tape to keep them together and allow to set for 24 hours. Don’t go too heavy on the glue and you will only need to remove it later.

Buy Model Parts Online Now

As 3D printers are not perfect, I use a car bog to “bog” the parts of the model where the joins are. There would have been too much sanding involved or even too much removal of plastic making the model walls thin.

Give the bogged parts a sand with Wet and Dry 180 grit. No need to use water at this point unless you wish to. On the image above you can see the lines made by the 3D printer. Its these lines that we plan to remove to give an exceptional finish throughout the project.

If this is your first painting project, then my main tip is spending 90% of your time preparing and don’t load thick putty and paint coats. Many thin coats are better than one thick coat – trust me!

Using 180 grit and a soft block try and smooth any printer or join marks, but don’t go silly or too “deep”, just give it a rub over.

Do the same with the hood, but notice the model uses a square mesh – you can round these little squares to make the overall finish look great. I never paint inside any of my models. What I would look at doing is coating the joints with the epoxy adhesive to make it more waterproof.

Once the PLA plastic has been worked on and to stop paint getting inside mask up the up the hull engine bay opening and cut out around the masking tape with a good sharp blade.

Undercoat the hull with any quick dry acrylic undercoat. Remember multiple thin coats is better than one thick coat. Don’t attempt to fill any imperfections with this coat. Allow 15 – 20 mins before touching and 1 hour between coats. Give it 3-4 coats then leave for 24-48 hours. Acrylic paint takes a lot longer to dry on PLA plastics than the can suggest. Believe me.

Do the same to the hood and avoid any runs. If your new to spray painting then its worth doing a crash course on You Tube like this -

https://www.youtube.com/watch?v=qB_MtpaMYaY. Your preparation and technique will be the difference between a smooth slick finish, or one with runs and bubbles.

Do the other parts and after 24-48 hours lightly sand all parts with a 240 – 360 grit wet and dry sandpaper. I chose to do this sand dry, but you may want use water. Just ensure the parts are bone dry before any other coats. Maybe pop them in the sun for 20 minutes to make sure.

Now all automotive shops sell a spray putty of some sort. This is the best product to remove small imperfections and print lines like 3D printers make. I used 5-6 thin coat an hour apart to get the build-up required. I then waited 48 hours before I even touched the model. This stuff needs to dry all the way through. Its an acrylic putty, but if put on thick may bubble with other topcoats of paint and that’s a bad situation to be in! If you think its dry, then think again. Allow plenty of time for the solvents to leave the product on the model surface.

After you have spray puttied see if it needs another coat. Maybe a light coat will give you that extra finish. I used a variety of 180 – 360 grit wet and dry paper to do the initial sand then moving and staying with 800 grit. I used my hand opposed to a soft sanding block to start to mould the hull nose and hood to get that typical ski finish. Take your time here.

I am now ready to give the hull a first coat. I have a 1983 red 550 so you can guess what colour mine will be. It would be great if you can share your colours on our Facebook page!

https://www.facebook.com/jetski.army

Now here is a warning. Don’t be impatient like I was. NEVER put masking tape onto paint that has not been on for more than 24-48 hours. These acrylic paints do not dry as fast as suggested on PLA plastic and whilst it may feel dry underneath, it is not. We have also caked on a few different products like undercoat, filler, topcoat and next a clear. You need to allow the paint solvents to fully leave before you mask up anything otherwise you get the pruning you see on the image above.

Buy Model Parts Online Now

Do yourself a favour and slow down. It’s worth the wait. If this does happen to you it’s a case of letting it dry 100% and then hitting it carefully with 1200 wet and dry using water. If this happens on a clear coat like it did for me, then sand carefully as if you break through the clear into the base colour you’re in a lot of bother.

I wanted a white underneath. Over the day I added 5-6 thin coats until it looked thick enough. I allowed at least 1 hour between coats and used an acrylic quick dry paint. After waiting at least 2 days I masked the base and worked on the top in red acrylic quick dry. Again waiting 1 hour between coats being careful no to spray to thick causing runs. By spending 90% of my time in preparation the coast went on well with a smooth glossy finish.

After leaving the model dry for another 2 days, I wore plastic medical type gloves to ensure body oils were not on the model applied a clear coat. Just like the colour coat I layered 3-4 thin clear coats and walked away. Don’t touch it. Close the room and leave as if you don’t you will keep adding more and likely stuff it up! Again, believe me!

Once the clear coat is dry its time to check for final imperfections. I had a bubble appear, so I hit it with wet and dry 1200 grit using water. Make sure you do not sand through the clear coat and colour to the undercoat otherwise you’re in a world of trouble. Then give another final coat using clear and walk away.

I found that split pins or pop rivet stems work as great handlebars as well as suitable shafts for the handle poles. We have included some in the kit for you. Using M1 screws or bolts I attached the pole to the hood.

I wanted a black mat on this model. I found a plate mat (something you would put on the dining room table) from the cheap shop. Measured and cut out a mat choosing to leave the sides. I wouldn’t be surprised if someone finds a thin Hydroturf type material – let us all know on Facebook.

Using the standard type of contact glue in a can, I sprayed the bottom of the mat thick, then put it into place quickly removing it to coat both sides. Used a pencil to hold the mat back allowing both sides to dry for 5 minutes then place and stick down.

Using the M1 screws provided (man those things are tiny!), insert and use glue to keep them in place. Feel free to mess with a M1 nut, but they are so small I opted for glue. Works a treat.

Push the pole pin through (I would push this through before you paint and also after you paint to remove any residue in the hole) thats provded allowing the pole to pivot.

And finally use a rubber oring thats also provided to put on the hood. We have included a few spares in the bag of tricks as well as a hood seal and larger rubber ring if you want to make this waterproof!

I decided to keep the jet pump off the back until I went full radio controlled. This design is close to my 550, but we will work on a proper 550 model in the future. The hood needs some shaping – but hey that killed 2 weeks in COVID-19 lockdown!

The next article will show how to make the model a true RC model. The current model comes with a bunch of impellers to try as well as mounts for a servo and motor, but looking

on eBay there are even real jet pumps.

If you do not have access to a printer Jetski Army will print them for you and put in the post.

Buy Model Parts Online Now

Once you have made your models please share online at the Jetski Army Facebook page or leave a comment below.

Enjoy!